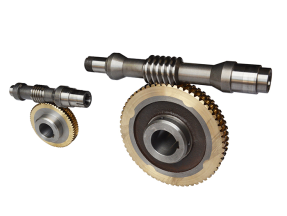

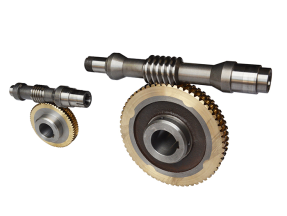

Worm gears and worm mechanisms are often used in situations where two shafts are interlocked, the transmission ratio is high, the transmission power is not high, or intermittent work is required. Widely used in machine tools, automobiles, instruments, metallurgical machinery, and other machinery or equipment, the reason is that the use of wheel axle motion can reduce force consumption. The common problems with worm gear and worm gear are as follows:

1. Gearbox oil leakage

In order to improve efficiency, worm gear reducers generally use non-ferrous metals as the worm gear, while the worm gear is made of harder steel. Due to the sliding friction transmission, a significant amount of heat is generated during operation, causing differences in thermal expansion between the various parts and seals of the reducer, resulting in gaps between the mating surfaces. As the temperature increases, the lubricating oil becomes thinner, which can easily lead to leakage. The main reasons for this situation are the unreasonable combination of materials, poor quality of the meshing friction surface, incorrect selection of lubricating oil dosage, poor assembly quality and usage environment.

2. Worm gear wear

Worm gears are generally made of tin bronze, and the paired worm material is quenched with 45 steel to HRC45~55, or quenched with 40Cr to HRC50~55, and then ground by a worm grinder to a roughness of Ra0.8 μ M. The wear and tear of the gearbox is slow during normal operation, and some gearboxes can be used for more than 10 years. If the wear rate is fast, it is necessary to consider whether the selection is correct, whether it operates under overload, as well as the material, assembly quality, or usage environment of the worm gear and worm gear.

3. Gear wear

It generally occurs on vertical mounted reducers, mainly related to the amount and type of lubricating oil added. When installed vertically, it is easy to cause insufficient lubricating oil. When the reducer stops running, the transmission gear oil between the motor and the reducer loses, and the gears do not receive the necessary lubrication protection. When the reducer is started, the gears may experience mechanical wear or even damage due to ineffective lubrication.

4. Worm bearing damaged

When a malfunction occurs, even if the gearbox is well sealed, it is often found that the gear oil inside the gearbox is emulsified, and the bearings are rusted, corroded, and damaged. This is because after running for a period of time, the gear oil temperature rises and then cools, resulting in a mixture of condensed water and oil. Of course, it is also closely related to the quality of bearings and assembly technology

Worm gear and worm gear

Dongguan Sanhe Machinery Co., Ltd

Main productsCopper sleeve, copper bearing, copper worm gear, copper guide plate, copper ball seat, copper nut, etc

Scope of supporting services: punching and forging machine tools, powder forming machinery, die-casting and peripheral spray machinery, rubber and plastic machinery, mining, metallurgical machinery, engineering machinery, air, port and marine equipment, recreation facilities, die cutting, printing machinery, etc.